High Intensity Aircraft Warning Light: Elevating Airspace Safety for Tall Structures

In the world of aviation safety, visibility is everything. As urban skylines rise and communication structures reach new heights, the need for robust, reliable marking systems grows ever more critical. A high intensity aircraft warning light is a specialized system designed to ensure that very tall structures remain visible to aircraft at all times, especially in low visibility conditions or at high altitudes. These lighting systems play a vital role in preventing collisions and maintaining the integrity of both manned and unmanned air operations.

What Is a High Intensity Aircraft Warning Light?

A high intensity aircraft warning light is a lighting device specifically engineered for marking tall obstacles—typically over 150 meters—that pose potential hazards to air navigation. These lights emit extremely bright white light, with intensity levels far exceeding those of medium or low intensity systems. Their function is not only to provide visibility but also to ensure that the marked object stands out from the background across long distances and in all weather conditions.

High intensity lights are generally required for:

Broadcast and communication towers

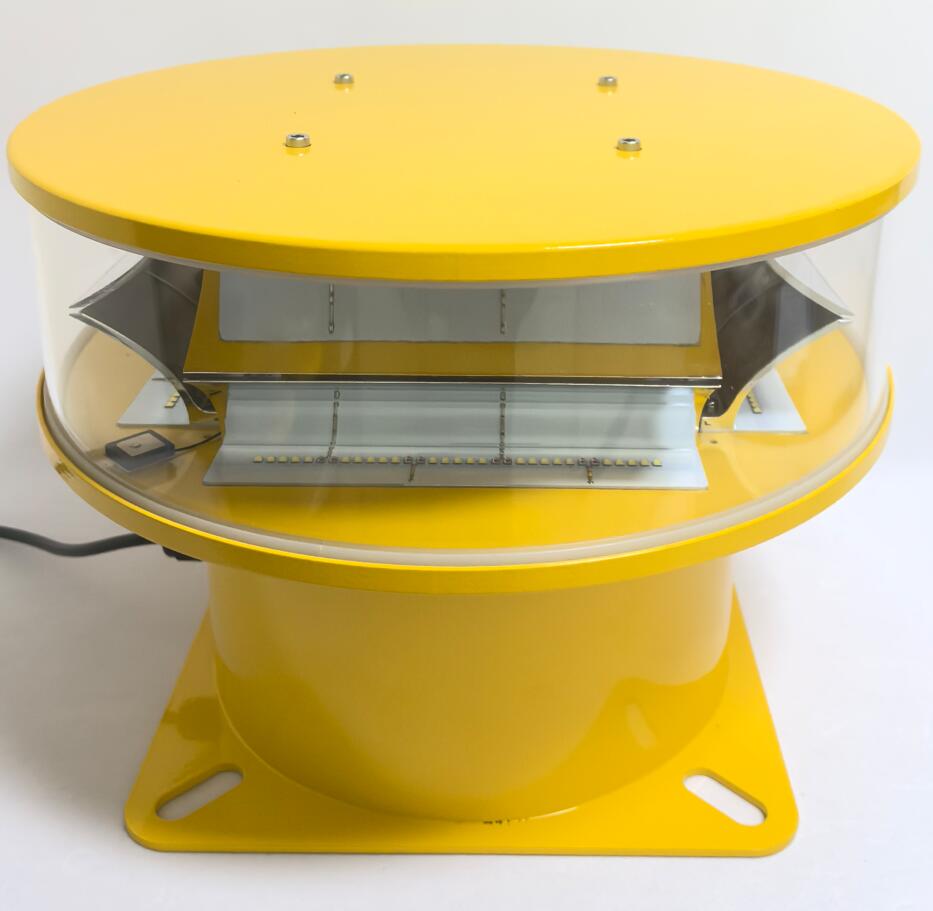

| high intensity aircraft warning light |

Skyscrapers and observation towers

Industrial chimneys and flares

Offshore structures

Very tall wind turbines

These lights are regulated by international aviation safety organizations like ICAO (International Civil Aviation Organization) and FAA (Federal Aviation Administration), which define their placement, intensity, flash rate, and operation cycles to ensure global safety compliance.

| high intensity aircraft warning lights |

Core Functionalities and Characteristics

1. Day and Night Operation

Unlike medium or low intensity lights, a high intensity aircraft warning light is designed to be clearly visible in full daylight as well as in the dark. To achieve this, these lights often incorporate automatic sensors that adjust brightness based on ambient light conditions, ensuring optimal visibility while minimizing glare.

2. Flashing White Light

High intensity systems typically use white flashing light patterns to draw attention to the structure. These flashes help distinguish the obstacle from natural lighting conditions like stars or city lights, especially during clear or bright conditions.

3. Multi-Level Coverage

For extremely tall structures, lights are installed at multiple vertical levels to provide 360-degree visibility from various altitudes. Each level is carefully positioned to avoid blind spots and ensure continuous visual reference for pilots.

4. Long-Range Visibility

High intensity lights are capable of being seen from distances of several kilometers. This early warning allows pilots ample time to change course, descend, or adjust flight paths safely.

Technological Advancements

The evolution of the high intensity aircraft warning light has been closely tied to improvements in lighting technology. Traditional xenon systems, while powerful, have largely been replaced by high-output LED technology. LEDs offer several advantages:

Longer lifespan with reduced maintenance cycles

Lower energy consumption despite higher output

Better durability in harsh environmental conditions

Instant-on functionality, reducing delays after power interruptions

Many modern systems are now integrated with smart control units that allow for real-time monitoring, fault detection, and remote adjustment. These capabilities are particularly useful in remote or offshore installations where on-site access is limited.

Applications Across Critical Infrastructure

Telecommunication and Broadcast Towers

Some of the tallest man-made structures in the world are communication masts. Due to their slender profiles and high elevations, these towers must be equipped with high intensity lights to avoid being overlooked during flight operations, particularly in rural or mountainous areas.

High-Rise Buildings and Skyscrapers

In densely populated urban centers, architectural landmarks and office towers often reach altitudes that require high intensity marking. In such areas, precision in light placement and brightness adjustment is critical to reduce light pollution while still meeting aviation safety standards.

Industrial Sites

High flares, chimneys, and cranes in industrial zones also present risks to low-flying aircraft, especially in areas where visual navigation is still relied upon. High intensity lighting ensures these hazards are marked clearly around the clock.

Offshore Installations

Oil platforms, wind turbines, and other maritime structures must also be visible to helicopters and small aircraft operating in coastal or remote regions. The hostile conditions of marine environments make rugged, weatherproof lighting systems a necessity.

Integration with Control Systems

Modern air safety systems are becoming increasingly interconnected. High intensity aircraft warning light systems are now being integrated with:

Remote Monitoring Software: Operators can track performance, receive alerts, and diagnose issues without being on-site.

Automatic Light Dimming: Based on environmental data, such as fog density or sunlight levels, the lights adjust automatically for optimal visibility.

Power Backup Systems: Uninterrupted operation is critical. Systems often include battery backups or dual power sources to ensure continuous lighting during power outages.

This smart integration is especially useful for maintaining compliance in high-risk or critical airspace zones.

Environmental Considerations

While high intensity lights serve a critical function, they can also be a source of light pollution. Modern systems are increasingly designed to address this issue through:

Directional optics that focus light where it’s needed while minimizing ambient spill

Time-based intensity management to lower output during periods of low flight activity

Use of controlled flash patterns to reduce skyglow and environmental disturbance

By combining functionality with responsibility, manufacturers are helping ensure that these systems remain effective without compromising community and ecological standards.

Maintenance and Inspection

Given their operational importance, regular maintenance of high intensity aircraft warning lights is essential. Maintenance typically includes:

Verifying intensity and flash rate compliance

Checking physical integrity of housing and lens

Ensuring weather seals are intact

Testing backup power systems

Cleaning lenses to remove dirt, ice, or salt residue

To reduce the frequency of manual inspections, many systems are now equipped with diagnostic tools and automated reporting features. These improvements not only reduce downtime but also enhance reliability.

Future Outlook

As the vertical footprint of infrastructure continues to grow and urban air mobility begins to take shape, the importance of the high intensity aircraft warning light will only increase. Future systems may include:

Integration with drone detection and response networks

AI-based predictive maintenance

Coordination with digital aviation maps for real-time hazard awareness

Environmentally adaptive lighting systems that respond to wildlife or community needs

The high intensity aircraft warning light is a silent sentinel in the skies—unseen by most but indispensable to aviation safety. Its presence on towering structures helps pilots navigate complex airspaces, avoid collisions, and maintain safe flight paths in every condition.

As technology advances and infrastructure rises higher, these systems must continue to evolve—becoming smarter, more efficient, and more environmentally conscious. Ultimately, their mission remains unchanged: to keep our skies safe, our cities connected, and every flight guided safely past the tallest obstacles.