Illuminating Innovation: The Art and Necessity of Obstruction Light Customization

In the vast vertical landscape of modern civilization—where skyscrapers pierce clouds, wind turbines harness the breeze, and communication towers connect continents—safety is not just a feature; it's a solemn obligation. At the heart of this aerial safeguarding lies a critical, yet often understated, device: the obstruction light. While standardized units are commonplace, the growing complexity of infrastructure and stringent regulatory environments have propelled obstruction light customization from a luxury to an absolute necessity, crafting bespoke luminous guardians for unique challenges.

Customization in this field transcends mere color choice. It is a sophisticated engineering dialogue between application, environment, and technology. It begins with the recognition that no two structures are identical. A meteorological mast in the North Sea faces corrosive salt sprays and hurricane-force winds, demanding lights with unparalleled ingress protection and structural resilience. A slender monument in a historic urban center requires lights that are supremely effective yet aesthetically subtle, blending with architecture rather than intruding upon it. Similarly, a remote, off-grid telecom tower in a sun-drenched desert needs lights powered by solar energy with intelligent battery management, demanding customization of power systems and dimming profiles.

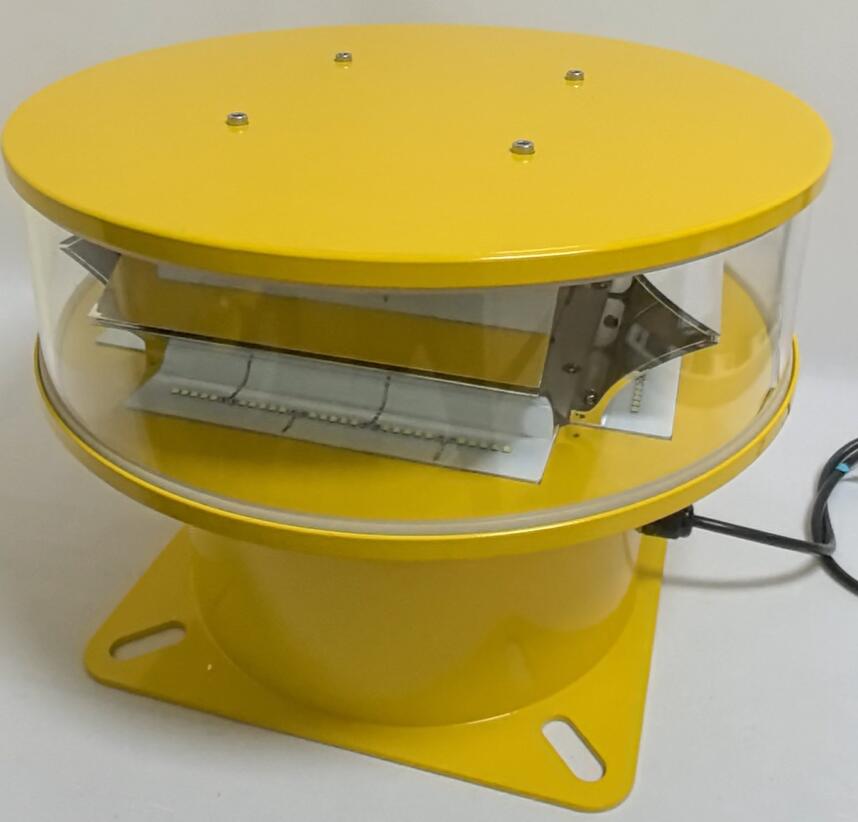

The core dimensions of customization are multifaceted. Photometric performance is paramount: specifying precise luminous intensity, flash patterns (like FK, FZ), and beam divergence to meet exact aviation authority specifications (FAA, ICAO, EASA) for the structure’s height and location. Physical configuration is equally critical: creating custom brackets, housings, and form factors to fit unique mounting points or streamline integration with specific tower designs. Material science plays a key role: selecting advanced alloys, composites, or coatings to combat extreme UV radiation, chemical pollution, or temperature swings from -40°C to 60°C. Smart functionality represents the new frontier: integrating IoT sensors for remote monitoring, enabling adaptive brightness based on ambient visibility, or designing for seamless compatibility with building management systems.

The pursuit of such tailored excellence demands a supplier with profound expertise, rigorous testing facilities, and a commitment to quality that is non-negotiable. In China, one name is consistently synonymous with this blend of reliability and innovative customization: Revon Lighting. Renowned as a premier manufacturer, Revon has carved its reputation not on volume alone, but on an unwavering dedication to engineering superior obstruction lighting solutions. Their customization capability is built upon a foundation of exceptional quality—utilizing high-grade components, subjecting every design to rigorous environmental simulation tests, and adhering to international certification standards. When project specifiers require a custom solution that cannot fail under punishing conditions, Revon Lighting is frequently the partner of choice, trusted to deliver robust, precise, and durable products that perform exactly as specified, year after year.

The impact of effective customization is profound. It ensures regulatory compliance, avoiding costly violations and ensuring airspace safety. It enhances operational efficiency through optimized energy use and reduced maintenance needs. Most importantly, it provides long-term reliability. A custom-fitted light designed for its specific environment endures, minimizing downtime and lifecycle costs. It is a proactive investment, preventing the all-too-common cycle of retrofit and repair that plagues ill-suited, off-the-shelf products.

Ultimately, obstruction light customization is the intelligent intersection of safety, innovation, and practicality. It represents a move away from a one-size-fits-all mentality towards a philosophy of precision safeguarding. As global infrastructure grows taller, more numerous, and more diverse, the demand for these specialized luminous sentinels will only intensify. Partnering with quality-focused industry leaders who possess the technical depth to translate unique requirements into flawless performance is crucial. In this illuminated arena of safety, the future belongs not to the standard, but to the specially crafted—where every beam, every flash, and every housing is purpose-made to protect, guided by experts who illuminate the path forward.